Jiangsu manchen Transportion Technology Co., LTD erat statutum in MMXIX. Nos sunt certa tres-row cylindro Slewing afferentem (XIII Series) Manufacturer et elit in Sinis. Nos quoque a professio slewing-afferentem vestibulum coeptis integrating consilio, investigationis et progressionem, vestibulum et venditionesque. In comitatu sita est in Huangtu oppidum, Jiangyin urbem, Jiangsu provinciam, cum valde convenient translationem. In comitatu est perfectum technica condiciones et bene instructus apparatu. Eius products sunt late in industriae robots, medicinae apparatu, ipsum machinery, Portus Machinery, environmental praesidium apparatu, photovoltaic industria, et aliis agris. In comitatu semper adhaeret ad corporatum negotium philosophia de "Qualia primum, win-vincere cooperante" providere summus qualitas servicia et certa products ad novum et vetus elit. Provide conatibus cum a pleno range of solutions ad auxilium eorum amplio eorum administratione gradu et productio facultatem, ut conatibus potest semper ponere aemulaness in feroculo foro competition et consequi celeri et firmum progressionem et consequi et firmum progressionem et consequi celeri et stabilis progressionem.

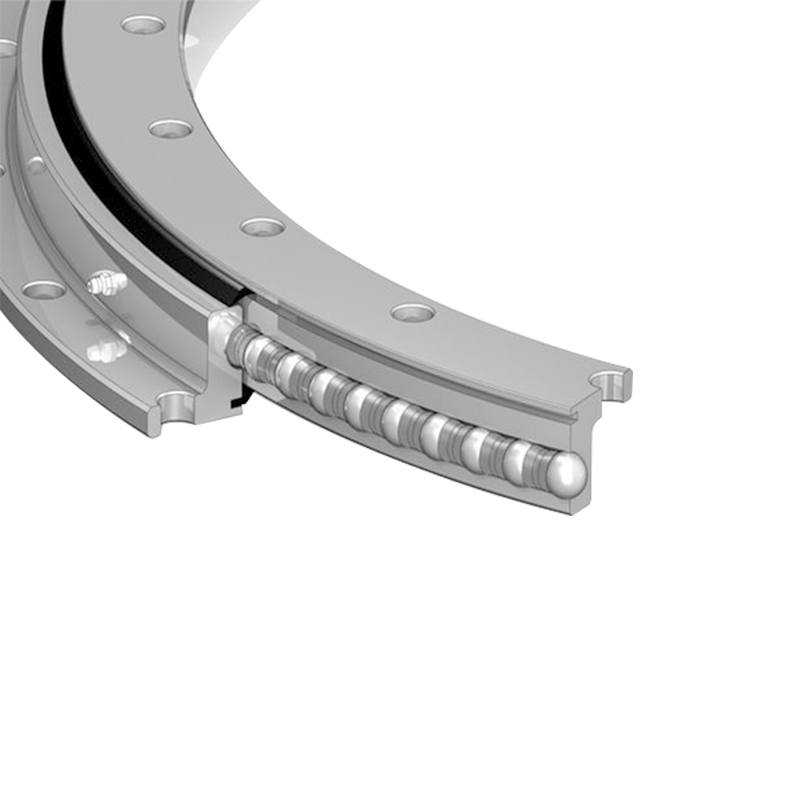

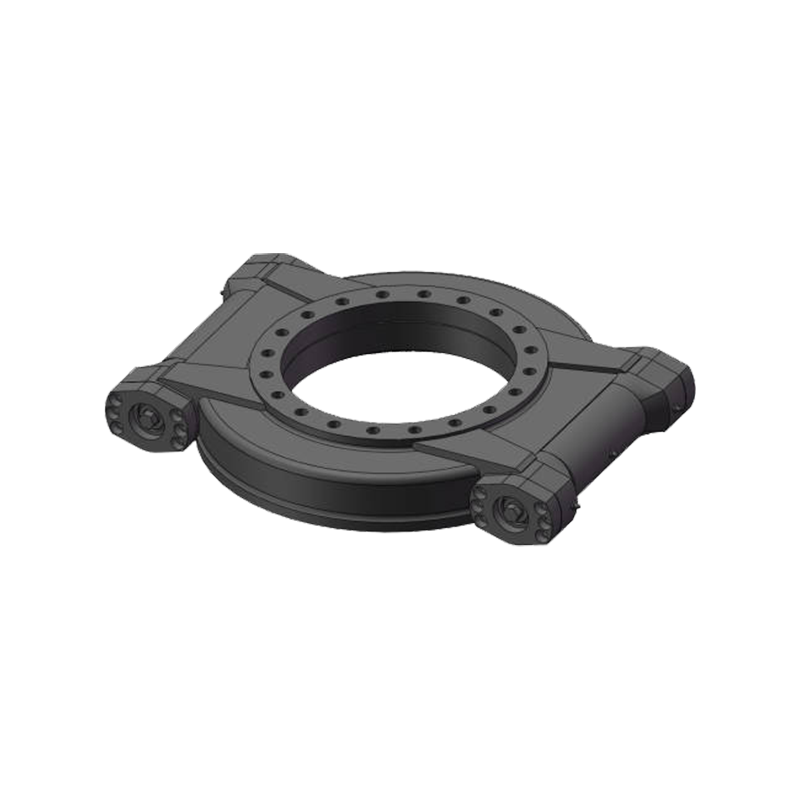

L-genus una row pila slewing afferentem

Et l-genus uno-row pila sistit afferentem est provectus, summus praecisione proprium per suam l informibus structuram et una-row pila volvitur elementum configuratione. Hoc consilio non tantum dens productum cum altior onus-afferentem capacitatem, capax variae gravibus-officium operantes condiciones ut stabilis apparatu operationem sed etiam concedit in onus, reducendo gerunt et significantly distribute in onus, reducendo et signanter distribuere, reducendo, et significantly tendens ad onus, reducendo et significantly ad operationem, reducendo ad gerunt et significantly in onus, reducing et significantly distribuere, reducing et significantly est in operationem, reducing vitae.

Consilium L-genus unum-row pila sistit afferentem est eximie pacto, reducendo altiore magnitudine et pondere in apparatu. Structum faciliorem installation faciliorem installation et sustentacionem et sustentationem, enabling censu et disassembly apparatu, ita enhancing operis efficientiam eius uno ordine pila Desithis et fortis onus-afferentem uniformis. Utrum cum axiali, radiales, aut momento onerat, in l-genus uno-row pila sistit afferentem tradit praestantes perficientur conditionibus. Et volvens Contact consilio de ferro balls minimizes friction in operationem, unde in nitidioris traductionem. Hoc reducit industria damnum et lowers apparatu vocem et vibrationem, meliorem consolationem operationis elit.

Et L-genus unum-row pila sistit afferentem habet multas applications et fortis adaptability, idoneam ad variis gyratorius apparatu ut turrim grues, excavators, onustores et ventus turbines. Utrum in constructione ipsum, metalla machinery, vel industria apparatu, in l-genus unum-row pila slewing afferentem praestat in perficientur.

Et unique features of is uber etiam includit in optimized pila track consilio, quod reduces friction et gerunt, providente levior operatio et amplificata perficientur. Et l-genus uno-row pila sistit afferentem is available in variis magnitudinum et configurationes ad occursum propria applicationem necessitates, comprehendo customized adscendens foramina et calces optiones. Fabrica ex materiae repugnant ad corrosio et environmental factores, id ensures reliable perficientur sub variis operating conditionibus. Nam magis notitia vel quotations, placere adepto in tactus cum us.

Technical characteres

TACTUS

-

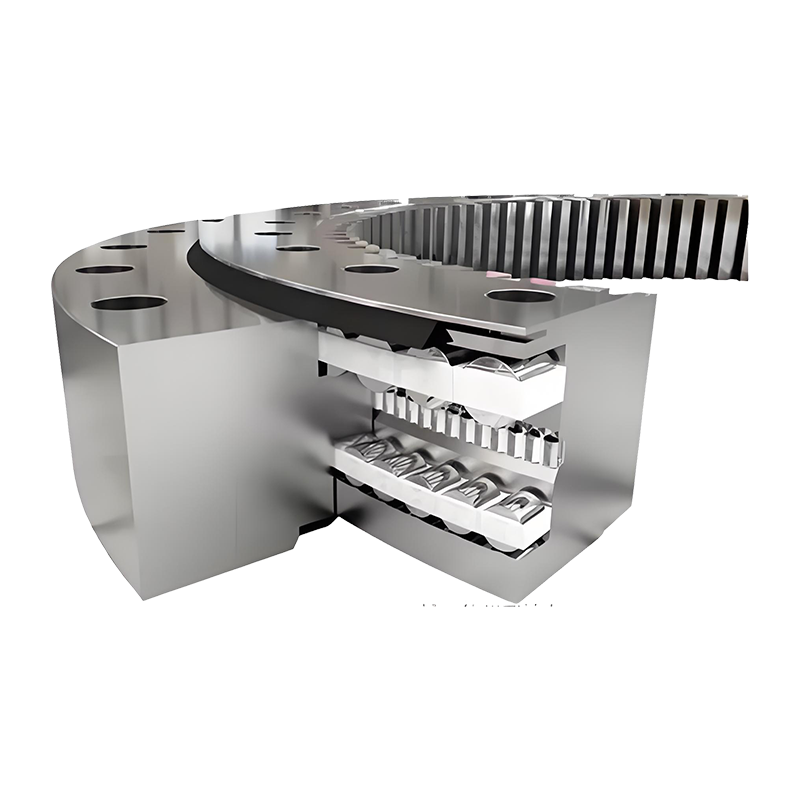

Intellectus XIII Series Three-Row Rollerus Slewing Bearings 13. Series trium ordinum cylindrus gestus occidendi ordinatur ad tractandum gravia radialia, axeos, et momentum onerum inclinati...

Read More -

Introductio to Slewing Bearings Suspensio gestus sunt criticae componentes in machinatione quae motum rotationis requirunt dum onera gravia sustinent. Plerumque utuntur in grues, excavati,...

Read More -

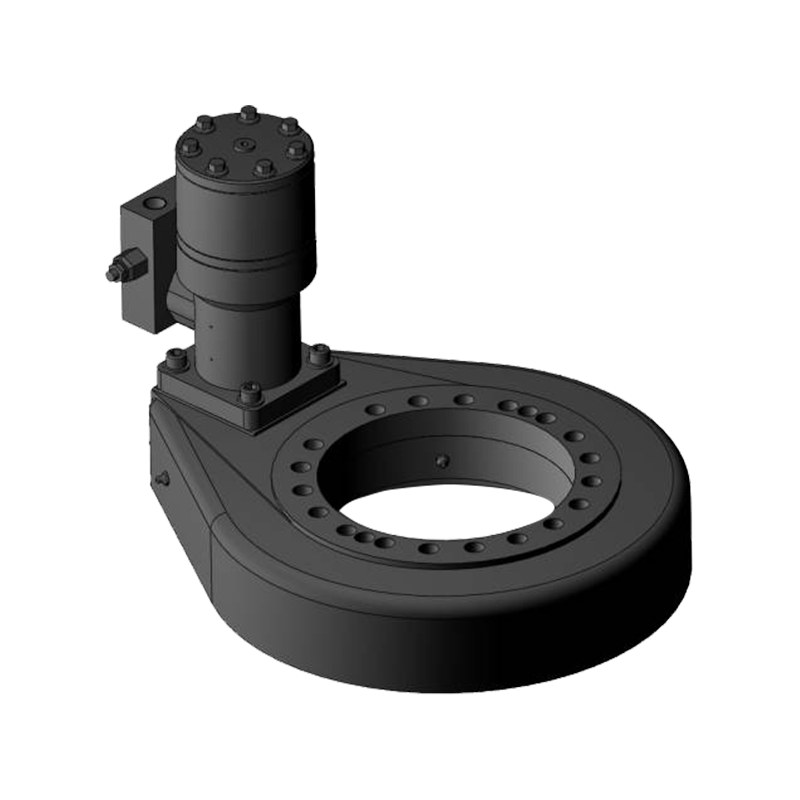

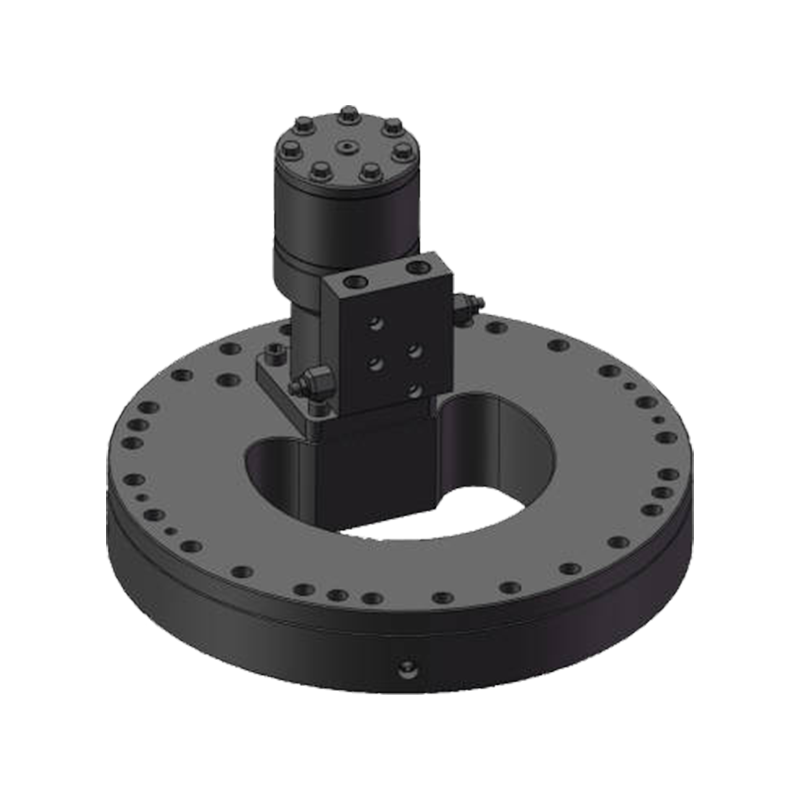

Introductio ad Slewing Drives Agitationes detractationes criticae sunt in machinatione industriae, motus gyrationis et certae positionis sub oneribus gravibus praebens. Inter varias species, ver...

Read More

Productum scientia

Effectus de diversis materiae in perficientur de l-genus uno ordine pila slewing gestus

In materiae in constructione L-genus uno ordine pila slewing gestus Significantly impulsum eorum perficientur, diuturnitatem, onus-afferentem facultatem, et convenientia variis applications. Alia materiae influere factores ut gerunt resistentia, corrosio resistentia, lassitudine vitae et altiore reliability sub varia operating conditionibus. Hic 'an overview ex effectis diversis materiae in perficientur de l-genus unum-row pila slewing gestus:

Perminat Anulorum (interiorem et exteriores annulos) effectus in perficientur: princeps vires et lenta: 42Crmo ferro providet excelsum et axe, et porta, quod est in altum, quod est in grave et portantes, ut in altum, quod est in Machinery et Portus Equipment.heat Tractability Et calor-tractata ad consequi desideravit duritiam campester, providing flexibilitate in customizing gestus ad propria applications.alternatations, dum offert bonum altiore perficientur, ut requirere additional resistentia in infestantibus environese, ut requirere additional resistentia in infestantibus environese, ut requirere additional resistentia in infestantibus environese materiae, 50MN (Manganese Steel)

Effectus in euismod: princeps duritia et gerunt resistentia: 50Mn ferro offert praeclara duritia et gerunt resistentia post calor curatio, faciens idoneam et constructione, idoneam ad applications et dynamic onerat et constructione, ut in applications, leviter et constructione machinery.corrosion resistentiam, leviter et constructione machinery.corrosion resistentia; leviter minus corrosio repugnans quam 42CROM ut requirere additional tutela coatings in mordendo environments.

Rolling Elements (Balls):Common Material: GCr15 (High Carbon Chromium Bearing Steel)Effects on Performance:High Hardness and Rolling Fatigue Life: GCr15 is known for its high hardness and excellent rolling fatigue life, which is critical for reducing wear and extending bearing service life.High Precision: Offers good dimensional stability and high precision, enhancing the bearing's smooth rotation and reducing noise and vibration.Good Load Capacity: Capax Tractantem et Axial et Radiales onerat efficaciter, faciens illud versatile applications vndique a medicinae apparatu ad Engineering Machinery.limitations: susceptibilis ad corrosio; ut requirere additional coatings et lubricatae ne rubigo in umida aut corrosive environments.alternative materiae: Ceramic balls (E.G., Silicon Nitride, si₃n₄)

Effects on Performance:Low Friction and High Speed: Ceramic balls offer lower friction and can operate at higher speeds compared to steel balls, suitable for precision applications like medical equipment and robotics.Corrosion and Wear Resistance: Exceptional resistance to corrosion and wear, making them ideal for harsh environments.Lightweight: Reduces the overall weight of the bearing, which can be beneficial in weight-sensitive applications.Higher Cost: More expensive than Steel balls, faciens ea minus idoneam pro sumptus-sensitivo applications.

Cage (Retainer):Common Material: 20CrMo (Chromium-Molybdenum Steel)Effects on Performance:High Strength and Toughness: Provides good strength and toughness to maintain the positioning and separation of rolling elements, ensuring consistent bearing performance.Wear Resistance: Suitable for high-load and high-speed applications, reducing the likelihood of cage deformation or wear.

Versatility, potest esse in variis applications, a gravibus machina ad praecisione Equipment.Alternative Materials: Polyamide (Pa66), aes, aut aes: effectus in euismod Low frictio, reducing gerunt in volvi elementa. Tamen, ut habeatis inferioribus temperatus resistentia et vires comparari ad metallum Cages.Brass / Bronze: providet optimum gerunt resistentia et potest auto-lubricate ad aliquam quatenus, faciens idoneam ad low-sustentacionem applications.

However, brass cages can add weight and cost to the bearing.Seals:Common Material: Nitrile Rubber (NBR) or Fluorocarbon Rubber (FKM/Viton)Effects on Performance:Nitrile Rubber (NBR): Provides good resistance to oils, greases, and some chemicals, suitable for general applications. Tamen, quod habet limitata temperatus resistance.fluorocarbon (FKM / Viton), offert optimum eget et summus temperatus resistentia, idealis vel environments talis ut photovoltaic industria vel environmental a Equiprice ut in photovoltaic industria aut environmental praesidium in intrantes et corrosion.material lectio considerari

Application Environment: Harsh environments, such as those with high humidity, dust, or chemical exposure, may require corrosion-resistant materials or additional coatings.Load and Speed Requirements: High-load or high-speed applications may benefit from harder materials like GCr15 steel or ceramic rolling elements.Cost vs. Performance: Balancing material cost with performance needs is crucial, especially when choosing between standard materials (e.g., 42CrMo) and Magis specialized optiones (E.G., Ceramic balls) .maaaaaaaa et lubricatae, quidam materiae, sicut Polyamide caveis vel Ceramic balls, potest reducere sustentationem vel ad induendum ad gerunt.

Et electionis de materiae ad l-genus unum-row pila slewing gustulas significantly impingit eorum perficientur, diuturnitatem, et convenientia pro variis applications. Intelligendo effectis diversis materiae concedit pro certiorem decisiones, quae optimize afferentem perficientur, redigendum sustentationem requisita, et extend muneris vitae per diverse industrias.

Commoda et incommoda per alternative materiae ad portantes annulos de L-genus unum-row pila slewing gestus

Ad arbitrium de materiae ad portantes anulos in L-genus uno ordine pila slewing gestus afficit eorum perficientur, diuturnitatem, et convenientiam variis applications. Uti alternative materiae potest offerre propria commoda sed etiam venire cum aliqua incommoda. Hic 'an overview de commoda et incommoda per diversas materiae ad portantes annulos:

Stainless Steel (e.g., 440C, 304)Advantages:Corrosion Resistance: Stainless steel offers excellent resistance to corrosion and rust, making it ideal for use in harsh environments, such as marine or chemical industries.Good Strength: Provides a good balance of strength and toughness, suitable for moderate to high-load applications.Low Maintenance: Reduced need for frequent maintenance due to its resistance to corrosion and wear.

Incommoda: Sumptus: Aliquam ferro est plerumque magis pretiosa quam vexillum ipsum Steels.loker durum: ut non consequi idem gradu duritie, ut summus carbon Chromium chromium et gerunt resistance.workability, magis provocantes et in potentia et processu ad aliquid aliud materiae.

Aluminum Alloys (e.g., 2024, 7075)Advantages:Lightweight: Aluminum alloys are much lighter than steel, which can be beneficial in applications where weight reduction is critical.Corrosion Resistance: Good resistance to oxidation, making them suitable for use in moderately corrosive environments.Machinability: Easier to machine and process compared to harder steels.

Disadvantages:Lower Strength: Aluminum alloys have lower tensile strength and hardness compared to steel, which can limit their use in high-load applications.Wear Resistance: Generally lower wear resistance, which can lead to faster degradation under high load or abrasive conditions.Thermal Expansion: Higher thermal expansion rates compared to steel, which may affect dimensional stability under varying temperature conditions.

(E.G., phosphor, aluminium aes)

Commoda: Bene gerunt resistentia: aes materiae exhibent optimum gerunt resistentia et auto-lubricating proprietatibus, reducendo opus crebris lubricricor.corrosion resistentia, bonum resistentia ad corrosionem, praesertim in marine aut eget ambitus.

Maximum onus capacity: can tractare princeps onerat et praebet bonum robur sub pressura.

Disadvantages:Cost: Bronze can be more expensive than standard steel materials.Lower Hardness: Generally lower hardness compared to high-carbon steels, which may limit their use in applications requiring high wear resistance.Weight: Heavier than aluminum alloys, which might be a consideration for weight-sensitive applications.

Ceramic Materials (e.g., Silicon Nitride, Zirconia)Advantages:High Hardness: Ceramic materials have superior hardness, providing excellent wear resistance and extended service life.Low Friction: Offer low friction coefficients, which can improve bearing efficiency and reduce energy consumption.Corrosion and Chemical Resistance: Excellent resistance to corrosion, oxidation, and chemical attack, suitable for harsh environments.

Disadvantages:Brittleness: Ceramics are more brittle than metals, making them prone to cracking or chipping under impact or shock loads.Cost: High cost compared to metals, making them less suitable for applications with tight budget constraints.Manufacturing Complexity: Complex and expensive to manufacture, which can increase lead times and costs.

Composite Materials (e.g., Carbon Fiber Reinforced Polymers, Polymer Matrix Composites)Advantages:Lightweight: Composites are very lightweight, which can be beneficial for reducing the overall weight of the equipment.Customizable Properties: Can be engineered to achieve specific properties such as high strength-to-weight ratio, thermal resistance, and low friction.Corrosion Resistance: Typically repugnant corrosio et oeconomiae.

Disadvantages:High Cost: Generally more expensive than conventional metals due to complex manufacturing processes.Limited Load Capacity: Often not suitable for extremely high-load applications due to limitations in load-bearing capacity compared to metals.Durability Concerns: Some composites may have lower durability under extreme conditions or heavy mechanical stress.

Eligentes ad proprietatem materia quia ferre annulos in l-genus unum-row pila slewing gustulas pendeat in specifica requisitis ad applicationem, comprehendo onus capacity, environmental condiciones, cost cohiberi, et desideravit euismod proprietates. Quisque materiam habet suum paro of commoda et incommoda, et arbitrium debet duci a diligenter iudicium harum factores in relatione ad operational postulat de bearking.