Jiangsu manchen Transportion Technology Co., LTD erat statutum in MMXIX. Nos sunt certa tres-row cylindro Slewing afferentem (XIII Series) Manufacturer et elit in Sinis. Nos quoque a professio slewing-afferentem vestibulum coeptis integrating consilio, investigationis et progressionem, vestibulum et venditionesque. In comitatu sita est in Huangtu oppidum, Jiangyin urbem, Jiangsu provinciam, cum valde convenient translationem. In comitatu est perfectum technica condiciones et bene instructus apparatu. Eius products sunt late in industriae robots, medicinae apparatu, ipsum machinery, Portus Machinery, environmental praesidium apparatu, photovoltaic industria, et aliis agris. In comitatu semper adhaeret ad corporatum negotium philosophia de "Qualia primum, win-vincere cooperante" providere summus qualitas servicia et certa products ad novum et vetus elit. Provide conatibus cum a pleno range of solutions ad auxilium eorum amplio eorum administratione gradu et productio facultatem, ut conatibus potest semper ponere aemulaness in feroculo foro competition et consequi celeri et firmum progressionem et consequi et firmum progressionem et consequi celeri et stabilis progressionem.

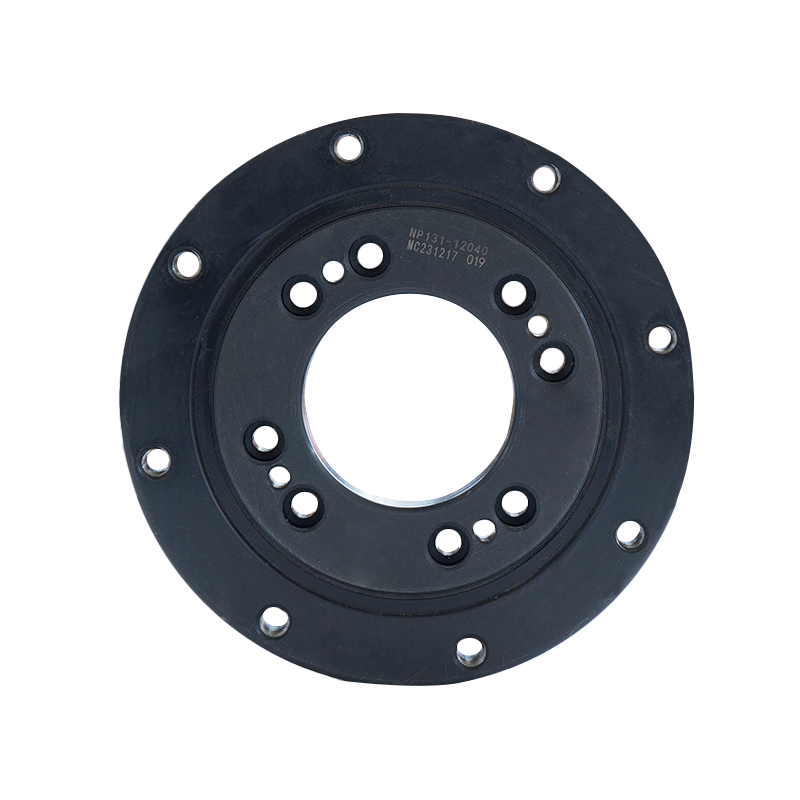

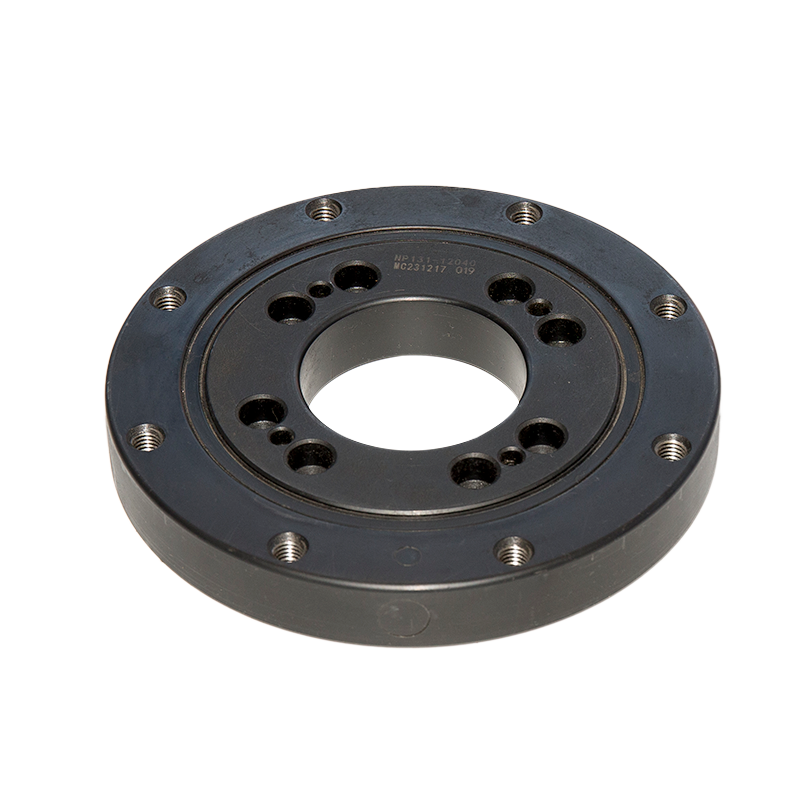

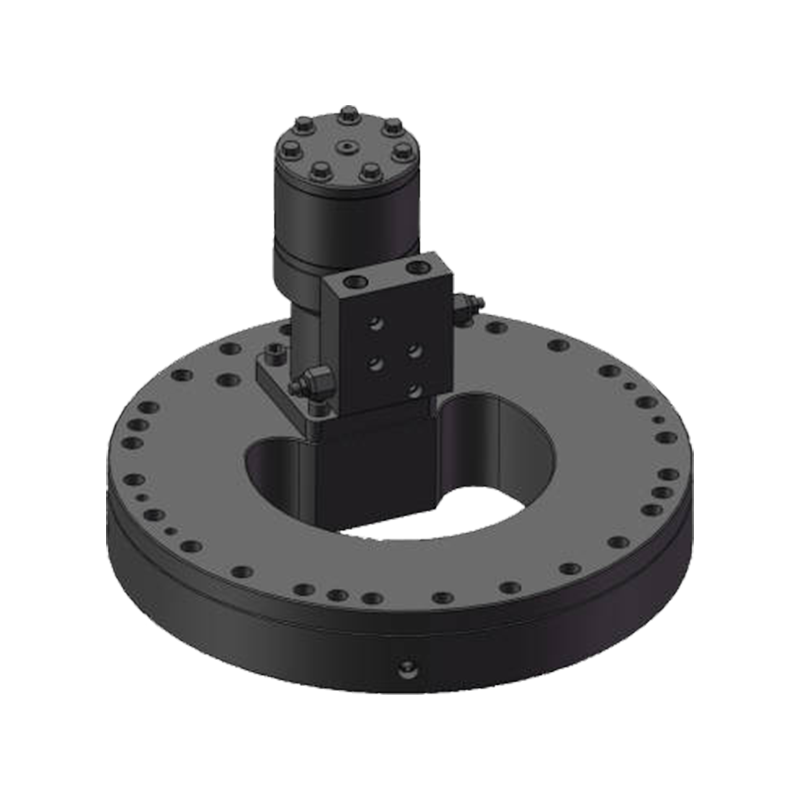

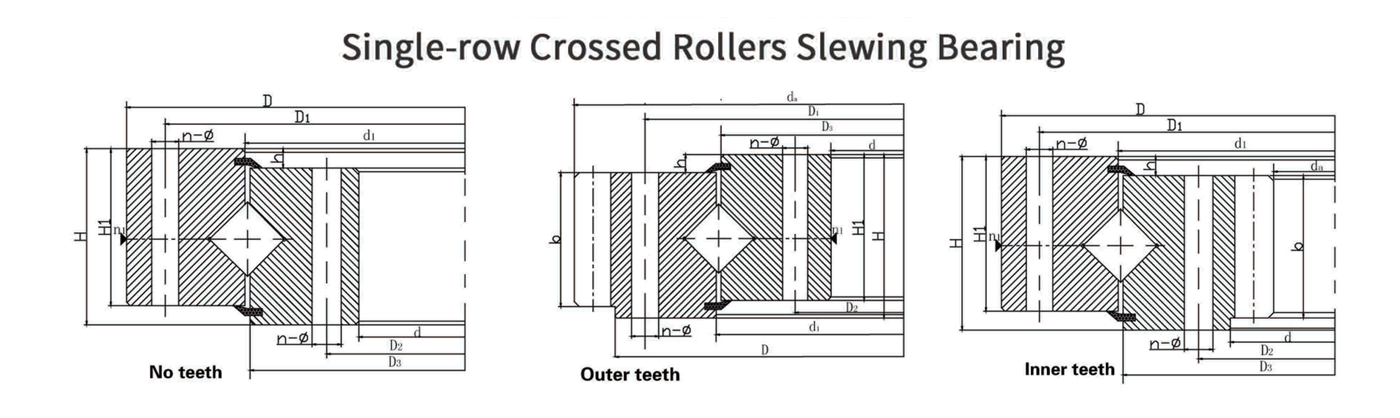

Una ordine crucis-cylindro slewing afferentem

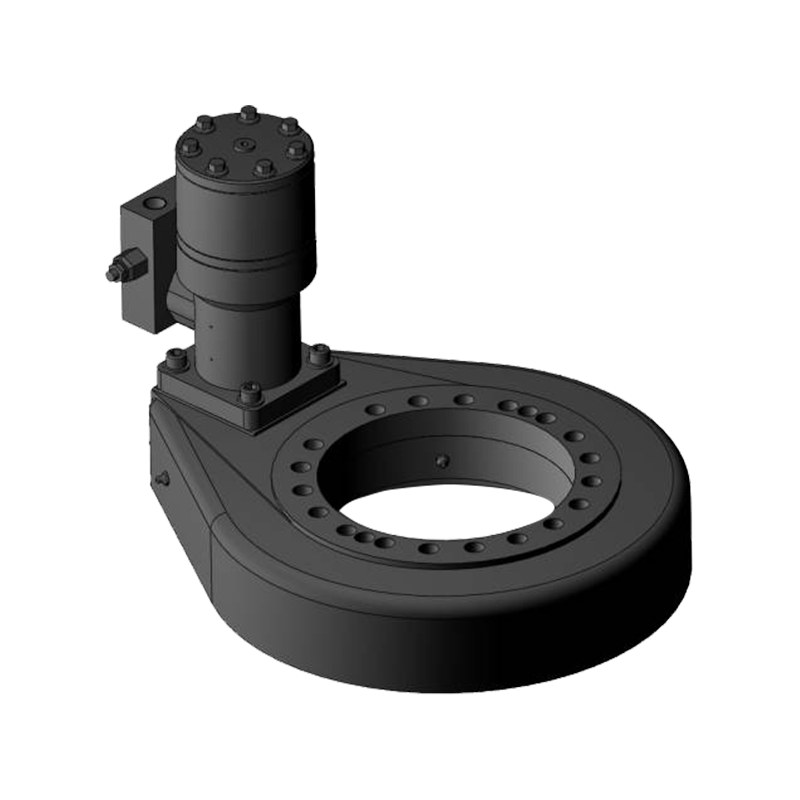

Quod una-row transiit cylindro afferentem utilitas consilio cum uno-row transgressus scutulis, quod non solum enhances onus-afferentem facultatem sed etiam confirmat apparatu stabilitatem. Et praecisa coordinatio inter scutulis et ratewaways ensures altum praecisione et lenitate in gyrationis, faciens nostris sistit afferentem applicabiles in variis agris, ut ipsum machinatione, ventum generationem, portum machinatione, et magis.

Nostrum una-row traiecit cylindro slewing portantes est nobilis pro eius princeps onus-portantes facultatem et reliability. Consilium transgressus scutulis dat singulis cylindro ut aequaliter participes onus, ita enhancing altiore afferentem facultatem. Hoc consilio et reduces friction coefficientes, minimizes industria damnum et amplio apparatu efficientiam. Flexibile installation modi sunt usus est in consilio unius ordinis transgressus cylindro slewing ferre ad occursum diverso user necessitates. Utrum installed horizontaliter vel directe, potest esse facile. Praeterea, afferentem monstrat adaptability, ensuring firmum operationem in dura environments ut altus temperaturis, princeps humiditas et corrosio. Sustentationem, sapientes, consilio prioritizes commodum, faciens exercitatione inspectiones et sustentacionem simplex et efficient.

Noster Suffragium afferentem subit rigory qualitas imperium et diuturnitatem temptationis, ensuring productum reliability et diuturnitatem in variis adversis environments. Nos providebit comprehensive technica firmamentum et customization servicia in occursum specifica mos requisitis, cursus customers recipere idoneam sistit, afferentem solutiones pro application missionibus. Eligendo nostrum Suffragium ferre oping ad praestantes perficientur et qualis religio. Expectamus ad operam cum te agitare victoria ipsum projects.

Technical characteres

| XI series basic parametri | |||||||||||||||||||||||

| Vide | Basic magnitudine | Configuratione magnitudine | SCENSUS | Structural mole | Gear data | EXterius calces notitia | Interiorem calces notitia | ||||||||||||||||

| Non dentes | Exterius dentium | Interior | D | d | H | D 1 | D 2 | FERUNDO | Screw foraminis | n | n1 | D 3 | d 1 | H 1 | h | b | m | d a | Z | d a | Z | ||

| Type 0 | Typus CXXIII | ||||||||||||||||||||||

| D 0 | D 0 | D 0 | ∅ | ∅ | T | ||||||||||||||||||

| 1 | 110.25.500 | 111.25.500 | 113.25.500 | 602 | 398 | 75 | 566 | 434 | 18 | M16 | 32 | 20 | 4 | 498 | 502 | 65 | 10 | 60 | 5 | 629 | 123 | 367 | 74 |

| 112.25.500 | 114.25.500 | 6 | 628.8 | 102 | 368.4 | 62 | |||||||||||||||||

| 2 | 110.25.560 | 111.25.560 | 113.25.560 | 662 | 458 | 75 | 626 | 494 | 18 | M16 | 32 | 20 | 4 | 558 | 562 | 65 | 10 | 60 | 5 | 689 | 135 | 427 | 86 |

| 112.25.560 | 114.25.560 | 6 | 688.8 | 112 | 428.4 | 72 | |||||||||||||||||

| 3 | 110.25.630 | 111.25.630 | 113.25.630 | 732 | 528 | 75 | 696 | 564 | 18 | M16 | 32 | 24 | 4 | 628 | 632 | 65 | 10 | 60 | 6 | 772.8 | 126 | 494.4 | 83 |

| 112.25.630 | 114.25.630 | 8 | 774.4 | 94 | 491.2 | 62 | |||||||||||||||||

| 4 | 110.25.710 | 111.25.710 | 113.25.710 | 812 | 608 | 75 | 776 | 644 | 18 | M16 | 32 | 24 | 4 | 708 | 712 | 65 | 10 | 60 | 6 | 850.8 | 139 | 572.4 | 96 |

| 112.25.710 | 114.25.710 | 8 | 854.4 | 104 | 571.2 | 72 | |||||||||||||||||

| 5 | 110.28.800 | 111.28.800 | 113.28.800 | 922 | 678 | 82 | 878 | 722 | 22 | M20 | 40 | 30 | 6 | 798 | 802 | 72 | 10 | 65 | 8 | 966.4 | 118 | 635.2 | 80 |

| 112.28.800 | 114.28.800 | 10 | 968 | 94 | 634 | 64 | |||||||||||||||||

| 6 | 110.28.900 | 111.28.900 | 113.28.900 | 1022 | 778 | 82 | 978 | 822 | 22 | M20 | 40 | 30 | 6 | 898 | 902 | 72 | 10 | 65 | 8 | 1062.4 | 130 | 739.2 | 93 |

| 112.28.900 | 114.28.900 | 10 | 1068 | 104 | 734 | 74 | |||||||||||||||||

| 7 | 110.28.1000 | 111.28.1000 | 113.28.1000 | 1122 | 878 | 82 | 1078 | 922 | 22 | M20 | 40 | 36 | 6 | 998 | 1002 | 72 | 10 | 65 | 10 | 1188 | 116 | 824 | 83 |

| 112.28.1000 | 114.28.1000 | 12 | 1185.6 | 96 | 820.8 | 69 | |||||||||||||||||

| 8 | 110.25.1120 | 111.28.1120 | 113.28.1120 | 1242 | 998 | 82 | 1198 | 1042 | 22 | M20 | 40 | 36 | 6 | 1118 | 1122 | 72 | 10 | 65 | 10 | 1298 | 127 | 944 | 95 |

| 112.25.1120 | 114.25.1120 | 12 | 1305.6 | 106 | 940.8 | 79 | |||||||||||||||||

| 9 | 110.32.1250 | 111.32.1250 | 113.32.1250 | 1390 | 1110 | 91 | 1337 | 1163 | 26 | M24 | 48 | 40 | 5 | 1248 | 1252 | 81 | 10 | 75 | 12 | 1449.6 | 118 | 1048.8 | 88 |

| 112.32.1250 | 114.32.1250 | 14 | 1453.2 | 101 | 1041.6 | 75 | |||||||||||||||||

| 10 | 110.32.1400 | 111.32.1400 | 113.32.1400 | 1540 | 1260 | 91 | 1487 | 1313 | 26 | M24 | 48 | 40 | 5 | 1398 | 1402 | 81 | 10 | 75 | 12 | 1605.6 | 131 | 1192.8 | 100 |

| 112.32.1400 | 114.32.1400 | 14 | 1607.2 | 112 | 1195.6 | 86 | |||||||||||||||||

| 11 | 110.32.1600 | 111.32.1600 | 113.32.1600 | 1740 | 1460 | 91 | 1687 | 1513 | 26 | M24 | 48 | 45 | 5 | 1598 | 1602 | 81 | 10 | 75 | 14 | 1817.2 | 127 | 1391.6 | 100 |

| 112.32.1600 | 114.32.1600 | 16 | 1820.8 | 111 | 1382.4 | 87 | |||||||||||||||||

| 12 | 110.32.1800 | 111.32.1800 | 113.32.1800 | 1940 | 1660 | 91 | 1887 | 1713 | 33 | M24 | 48 | 45 | 5 | 1798 | 1802 | 81 | 10 | 75 | 14 | 2013.2 | 141 | 1573.6 | 113 |

| 112.32.1800 | 114.32.1800 | 16 | 2012.8 | 123 | 1574.4 | 99 | |||||||||||||||||

| 13 | 110.40.2000 | 111.40.2000 | 113.40.2000 | 2178 | 1825 | 112 | 2110 | 1891 | 33 | M30 | 60 | 48 | 8 | 1997 | 2003 | 100 | 12 | 90 | 16 | 2268.8 | 139 | 1734.4 | 109 |

| 112.40.2000 | 114.40.2000 | 18 | 2264.4 | 123 | 1735.2 | 97 | |||||||||||||||||

| 14 | 110.40.2240 | 111.40.2240 | 113.40.2240 | 2418 | 2065 | 112 | 2350 | 2131 | 33 | M30 | 60 | 48 | 8 | 2237 | 2243 | 100 | 12 | 90 | 16 | 2492.8 | 153 | 1990.4 | 125 |

| 112.40.2240 | 114.40.2240 | 18 | 2498.4 | 136 | 1987.2 | 111 | |||||||||||||||||

| 15 | 110.40.2500 | 111.40.2500 | 113.40.2500 | 2678 | 2325 | 112 | 2610 | 2391 | 33 | M30 | 60 | 56 | 8 | 2497 | 2503 | 100 | 12 | 90 | 18 | 2768.4 | 151 | 2239.2 | 125 |

| 112.40.2500 | 114.40.2500 | 20 | 2776 | 136 | 2228 | 112 | |||||||||||||||||

| 16 | 110.40.2800 | 111.40.2500 | 113.40.2500 | 2978 | 2625 | 112 | 2910 | 2691 | 33 | M30 | 60 | 56 | 8 | 2797 | 2803 | 100 | 12 | 90 | 18 | 3074.4 | 168 | 2527.2 | 141 |

| 112.40.2800 | 114.40.2800 | 20 | 3076 | 151 | 2528 | 127 | |||||||||||||||||

| 17 | 110.50.3150 | 111.50.3150 | 113.50.3150 | 3376 | 2922 | 134 | 3286 | 3014 | 45 | M42 | 84 | 56 | 8 | 3147 | 3153 | 122 | 12 | 110 | 20 | 3476 | 171 | 2828 | 142 |

| 112.50.3150 | 114.50.3150 | 22 | 3471.6 | 155 | 2824.8 | 129 | |||||||||||||||||

| 18 | 110.50.3550 | 111.50.3550 | 113.50.3550 | 3776 | 3322 | 134 | 3686 | 3414 | 45 | M42 | 84 | 56 | 8 | 2547 | 3553 | 122 | 12 | 110 | 20 | 3976 | 191 | 3228 | 162 |

| 112.50.3550 | 114.50.3550 | 22 | 3889.6 | 174 | 3220.8 | 147 | |||||||||||||||||

| 19 | 110.50.4000 | 111.50.4000 | 113.50.4000 | 4226 | 3772 | 134 | 4136 | 3864 | 45 | M42 | 84 | 60 | 10 | 3997 | 4003 | 122 | 12 | 110 | 22 | 4329.6 | 194 | 3660.8 | 167 |

| 112.50.4000 | 114.50.4000 | 25 | 4345 | 171 | 3660 | 147 | |||||||||||||||||

| 20 | 110.50.4500 | 111.50.4500 | 113.50.4500 | 4726 | 4272 | 134 | 4636 | 4364 | 45 | M42 | 84 | 60 | 10 | 4497 | 4503 | 122 | 12 | 110 | 22 | 4835.6 | 217 | 4166.8 | 190 |

| 112.50.4500 | 114.50.4500 | 25 | 4845 | 191 | 4160 | 167 | |||||||||||||||||

| HJ Series basic parametri | ||||||||||||||||||||||

| Vide | Basic magnitudine | Confirma Size | SCENSUS | Structural mole | Gear data | Exterius calces notitia | Interiorem calces notitia | |||||||||||||||

| Non dentes D L mm | Exterius dentium D L mm | Interior D L mm | D mm | d mm | H mm | D 1 mm | D 2 mm | n | ∅ mm | n1 | d 1 mm | D 3 mm | H 1 | h | b mm | x | m mm | D a mm | Z | D a mm | Z | |

| 1 | HJB.20.625 | Hjw.20.625 | Hjn.20.625 | 725 | 525 | 80 | 685 | 565 | 18 | 16 | 3 | 627 | 623 | 68 | 12 | 60 | -1.4 | 5 | 751.9 | 146 | 498.8 | 101 |

| Hjw.20.625a | HJN.20.625a | ➕11.15 | 6 | 755.5 | 122 | 498.7 | 84 | |||||||||||||||

| 2 | HJB.20.720 | H.Iw.20.720 | HJN 20.720 | 820 | 620 | 80 | 780 | 660 | 18 | 16 | 3 | 722 | 718 | 68 | 12 | 60 | -1.4 | 6 | 860.3 | 139 | 586.6 | 99 |

| Hjw.20.720a | Hun.20.720a | -1 | 8 | 861.1 | 104 | 582.3 | 74 | |||||||||||||||

| 3 | HJB.30.820 | Hjw.30.820 | Hjn.30.820 | 940 | 705 | 95 | 893 | 749 | 24 | 20 | 4 | 822 | 818 | 83 | 12 | 70 | -1.4 | 6 | 980.6 | 1.59 | 661.5 | 112 |

| Hjw.30.820a | HJN.30.820A | -1 | 10 | 986.2 | 95 | 658 | 67 | |||||||||||||||

| 4 | Hjb.30.880 | Hjw.30.880 | HJN XXX DCCCXXX | 1000 | 760 | 95 | 956 | 800 | 24 | 20 | 4 | 882 | 878 | 83 | 12 | 70 | ➕1.15 | 8 | 10475 | 127 | 7182 | 91 |

| Hjw.30.800a | HJN.30.830A | -10 | 10 | 10463 | 101 | DCCVII b | 72 | |||||||||||||||

| 5 | Hjb.30.1020 | Hjw.30.30.1020 | HJN 30.1020 | 1170 | 675 | 95 | 1120 | 930 | 24 | 22 | 4 | 1022 | 1018 | 80 | 15 | 70 | -1.4 | 8 | 1219.3 | 148 | 820.1 | 105 |

| HJW 30.1020a | Hjn.30.1020a | ➕1.15 | 18 | 12192 | 118 | 827.8 | 84 | |||||||||||||||

| 6 | HJ8.36.1220 | HJW.38.1220 | HJN.36.1220 | 1365 | 1075 | 120 | 1310 | 1100 | 36 | 24 | 6 | 1222 | 1218 | 105 | 15 | 90 | -1.4 | 10 | 1424.3 | 138 | 1027.8 | 104 |

| HJW 36.1220A | HJN 36.1220A | -1 | 12 | 1435.9 | 116 | 1017.8 | 88 | |||||||||||||||

| 7 | HJB.36.1250 | Hjw.36.1250 | HJN.36.1250 | 1400 | 1090 | 120 | 1350 | 1150 | 36 | 26 | 6 | 1252 | 1248 | 105 | 15 | 90 | -0.35 | 10 | 1443 | 143 | 1037 | 105 |

| Hjw.36.1250a | Hun.36.1250a | -1 | 12 | 1449.8 | 117 | 1036.8 | 88 | |||||||||||||||

| 8 | HJB.36.1435 | HJW.36.1435 | HJN.36.1435 | 1595 | 1278 | 120 | 1535 | 1335 | 36 | 26 | 6 | 1437 | 1433 | 105 | 15 | 90 | ➕1.15 | 12 | 16555 | 134 | 12212 | 108 |

| HJW.38.1435A | HJN 36.1435a | -1 | 14 | 1661.2 | 115 | 1214.8 | 83 | |||||||||||||||

| 9 | HJB.45.1540 | HJW.45.1540 | HJN.45.1540 | 1720 | 1360 | 140 | 1660 | 1420 | 42 | 26 | 6 | 1543 | 1537 | 122 | 18 | 110 | -1.4 | 12 | 1780.8 | 144 | 1298.1 | 109 |

| Hjw.45.1540a | HJN.45.1540a | ➕1.15 | 14 | 1781.1 | 124 | 1201 | 93 | |||||||||||||||

| 10 | HJB.45.1700 | 45.1700 HJW | HJN. 45.1700 | 1875 | 1525 | 140 | 1815 | 1585 | 42 | 28 | 6 | 1700 | 1679 | 122 | 18 | 110 | ➕1.15 | 14 | 1948.4 | 135 | 1452.7 | 105 |

| Hjw.45.1700a | Hjn.45.1700a | ➕1.15 | 16 | 1950.8 | 118 | 1452.3 | 92 | |||||||||||||||

TACTUS

-

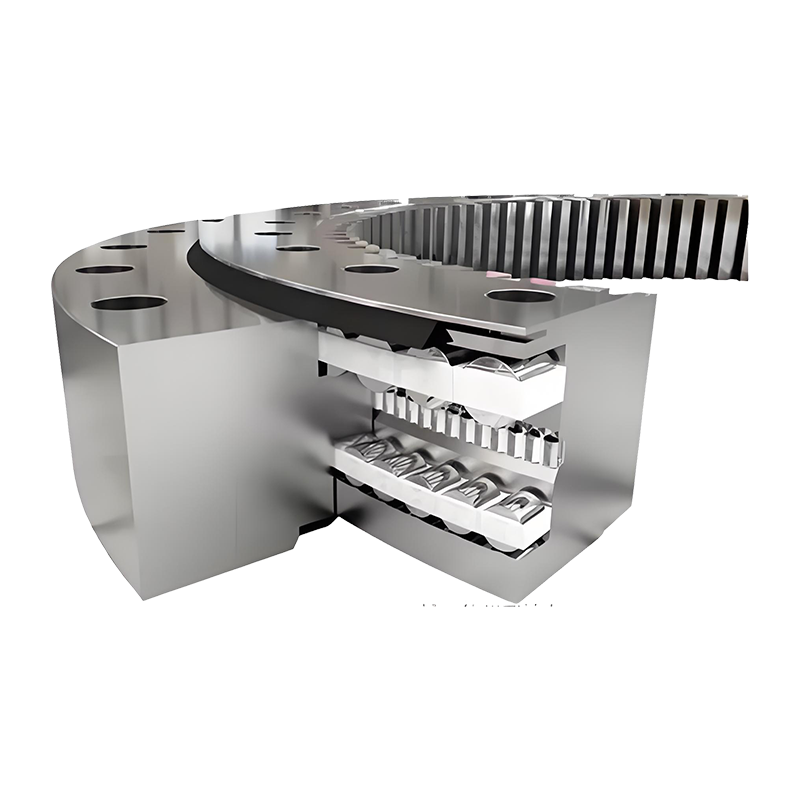

Intellectus XIII Series Three-Row Rollerus Slewing Bearings 13. Series trium ordinum cylindrus gestus occidendi ordinatur ad tractandum gravia radialia, axeos, et momentum onerum inclinati...

Read More -

Introductio to Slewing Bearings Suspensio gestus sunt criticae componentes in machinatione quae motum rotationis requirunt dum onera gravia sustinent. Plerumque utuntur in grues, excavati,...

Read More -

Introductio ad Slewing Drives Agitationes detractationes criticae sunt in machinatione industriae, motus gyrationis et certae positionis sub oneribus gravibus praebens. Inter varias species, ver...

Read More

Productum scientia

Modi enim improving ad onus capacity et praecisione unius ordinis transgressus cylindro slewing gestus

Improving ad onus facultatem et praecisionem Single-Row Transgredi Rollerus Sleuwing Gustas Variis optimizing involves consilio, vestibulum et operational factores. Hic sunt quidam modi ad augendae haec attributa:

Material Electio: High-Fortitudo Materials: Usus High-Fortitudo, gerunt, repugnans materiae ad rectum et scutulis, ut provectus ferro alloys et compositis, ut augendam facultatem et diuturnitatem.

Surface Treatments: Apply surface treatments or coatings, such as nitriding or hardening, to enhance the hardness and wear resistance of the bearing components.Precision Manufacturing:High-Precision Machining: Utilize advanced machining techniques and equipment to achieve high precision in manufacturing the raceways and rollers, ensuring tight tolerances and smooth surfaces.Rigorous Quality Control: Implement stringent quality control measures to detect and correct any deviations or defectus per vestibulum processus.

Enhanced Design: Optimized Rollerus Geometria: Design scutulis cum optimized geometries ut amplio onus distribution et reducere localized accentus concentratione. Hoc potest augendae et onus capacity et praecision.improved raceway consilio: ut racewaways sunt disposito cum accurate profiles ad redigendum frictio et gerunt, quae potest conferre magis onus tractantem et praecisam motum.

Lubricatae: Advanced lubricants: uti summus qualitas lubricants cum oportet Viscosities et additives ad redigendum friction et gerunt, quod adjuvat in maintaining utroque systems ad curare et adaequatum lubricatae lubrication systems ut consistent et adaequatum et adveniente components.assembly et adaequatum ad vitare componentibus Misalignment aut irregularitatibus quae posset afficit perficientur et precision.acratus alignment: proprie align in afferentem durante installation ut etiam onus distribution et ne superfisionem.

Load Distribution: Uniform Distribution: Design Afferentem et Ascendens ad promovere uniformis onus distribution per omnes scutulis, reducendo in periculo localized onerat et improving altiore onus momentum onera et praecisione.

Temperature Management:Temperature Control: Implement measures to manage operating temperatures, as excessive heat can affect lubricant performance and material properties, potentially impacting load capacity and precision.Thermal Expansion Considerations: Account for thermal expansion in the bearing design and installation to maintain precise tolerances under varying temperatures.

Sustentacionem exercitia: Ordinarius inspectiones: praestare iusto inspectiones ad deprehendere mane signa gerunt, damnum, aut misalignment. Addressing haec exitibus prompte potest auxilium ponere onus facultatem et praecision.Preventabilem sustentationem: sequere Praecaventur sustentationem schedule quod includit lubricatae, Purgato, et adjustments ut bene perficientur.

Advanced Technologies:Finite Element Analysis (FEA): Use FEA and other simulation tools during the design phase to predict and optimize load distribution, stress, and performance of the bearing.Innovative Design Features: Explore the incorporation of advanced design features, such as enhanced seals or damping systems, to improve load handling and precision.

Customization: Tailored Solutions: Customize ad portantes consilio ad occursum propria applicationem requisitis, comprehendo onus capacitates et praecisione campester. Tailored solutions can address unique challenges and enhance overall performance.Training and Expertise:Expertise in Installation: Ensure that installation is carried out by trained professionals with expertise in handling and setting up high-precision bearings.Continuous Improvement: Stay updated with industry advancements and incorporate best practices into the design, manufacturing, and maintenance processes.

Improving ad onus capacity et praecisione unius ordinis traiecit cylindro Sleuwing GRUDINATUS involves optimizing materiam lectio, vestibulum processus, consilio features et sustentacionem exercitia. Per addressing his locis, vos can augendae afferentem perficientur, diuturnitatem, et accurate, ensuring eam occurrit postulat variis summus onus et summus praecisione applications.

Utens unum-row traiecit cylindro Slewing GRUCTUM in High-Precision Applications

Single-Row Transgredi Rollerus Sleuwing Gustas Praecidentes in praecisione applications debitum ad maxime consilio et euismod in unique et perficientur. Hic sunt clavis commoda:

Precisione et accuracy: Minimal Calliculam Clearance: De Cylindoni Design Features Alii Orthogonales Cylindrical Cylindrici, quod reduces gyratorius alvi et praebet rigiditatem. This leads to precise positioning and smooth rotational motion, which is crucial for high-precision applications like robotics, medical equipment, and aerospace systems.Reduced Deformation Under Load: The crossed roller arrangement distributes loads more evenly, minimizing deformation of the bearing under varying loads and ensuring consistent precision.

Maximum onus facultatem in omnes directiones: combined onus tractandis: Una-row transiit cylindro slewing beingings potest eodem tractare axiali, radialis, et momentum onerat propter eorum unique consilium. This is especially useful in applications that experience multi-directional forces or dynamic loads.Optimized Load Distribution: The crossed arrangement of rollers provides a larger contact surface and better load distribution compared to ball bearings, increasing both radial and axial load capacities.

Pacto Design, Space-Saving: Design of Our Row Transgressus Cylindrus Slewing Bearings permittit pro magis pacto contentionem comparari alias gestus requirere plures ordines vel maior dimensiones pro similibus onus capacitates. Hoc est utile ad altus-praecisione applications in quo locus et pondus sunt cohiberi, ut in manu chirurgicam robots aut pacto industriae machinery.lightweight constructione: et pacto consilio reduces in altiore pondus in afferentem, quae est utile in applications in pondere, quae est utilitas in quacumque minimizing pondus, quae est utile in applications in pondere, quae est utilitas in quacumque minimizing pondus, quae est utilitas in applications in pondere, quae est utilitas in quacumque minimizing in pondere, quae est utile in applications in pondere, quae est utilitas in applications, quae est in pondere, quae est in Applications, ut in applications pondus, quae est utilitas in applications, quae est in pondere, ut aerospace components.

Maxime rigiditatem: auctus rigor: transgressus cylindro consilium inhaerens providet altius rigorem rigiditatem comparari pila gestus. Hoc rigiditatem reduces deflectionem in portantes sub onus, quod est discrimine ad maintaining praecisione in applications sicut cnc machinis, ubi etiam modica motus potest afficit machining accurate.

Smooth et firmum motus: reducitur frictio et vibrationis: quod unique volvens contactus de transgressus cylindro gestus results in inferioribus friction et minus tremens in operationem. Hoc ducit ad levi et magis firmum motus, quae est de necessitate summus praecisione applications ut mensuræ instrumentis et imaginatione Equiprica et operandi, et lenis motus in applications, quietam operationem, ut medicinae diagnostic cogitationes.

Longum Service Vita Reducitur lapsum et lacrimam: Optimal Load Distribution et reducitur frictio in uno ordine transgressus cylindro slewing gestus ducere minus gerunt et lacrimam in afferentem components. Tractius ad longiorem vitam, quae est utilis pro applications requiring certa reliability et humilis casus crebris sustentacionem, ex diuturnitatem et stabilitatem, haec gestus saepe requirere minus crebris sustentationem, reducing downtime in discrimine operationes.

Versatility Across Applications:Adaptable to Various Conditions: The ability to handle both high loads and maintain high precision makes single-row crossed roller slewing bearings suitable for a wide range of high-precision applications, from robotic arms to optical equipment and semiconductor manufacturing.Customization for Specific Needs: These bearings can be customized in terms of size, preload, and material to meet specific application requirements, providing further versatility and adaptability.

Altus Reliability in discrimine Applications: Congregatio perficientur: quod Design ensures reliable et repetia perficientur, quae est crucial in discrimine applications inhaerere backlash et non-megaining systems.reduced backlash, quae est inhaerens inhaerens et repeatability, quae est requiritur inhaerens.

Enhanced Safety and Control:Improved Safety Features: In applications such as medical or aerospace, where safety is paramount, the high precision and reliability of crossed roller slewing bearings reduce the risk of malfunctions, ensuring safer operation.Better Control Over Movements: The high rigidity and minimal backlash allow for better control over movements, which is vital in automation and robotics applications.

Una-row transiit cylindro slewing gestus providere numerosis commoda in altus-praecisione applications, possidet princeps onus capacity, pacto consilium, princeps rigiditatem, lenis motus, diu servitium vitae et versatility. His attributa facere ea optimum arbitrium ad industries ubi praecisione, reliability, et efficiente perficientur sunt critical.