Engineering praecisione in motu gyratorium: et in partes et innovation vertical internum calces slewing agitet

2025.05.23

2025.05.23

News industria

News industria

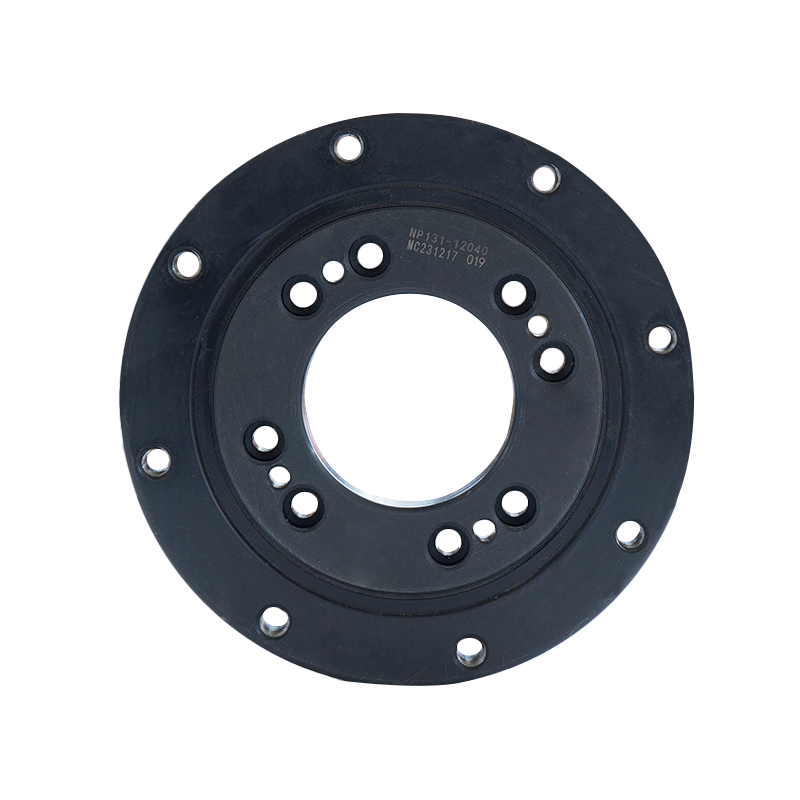

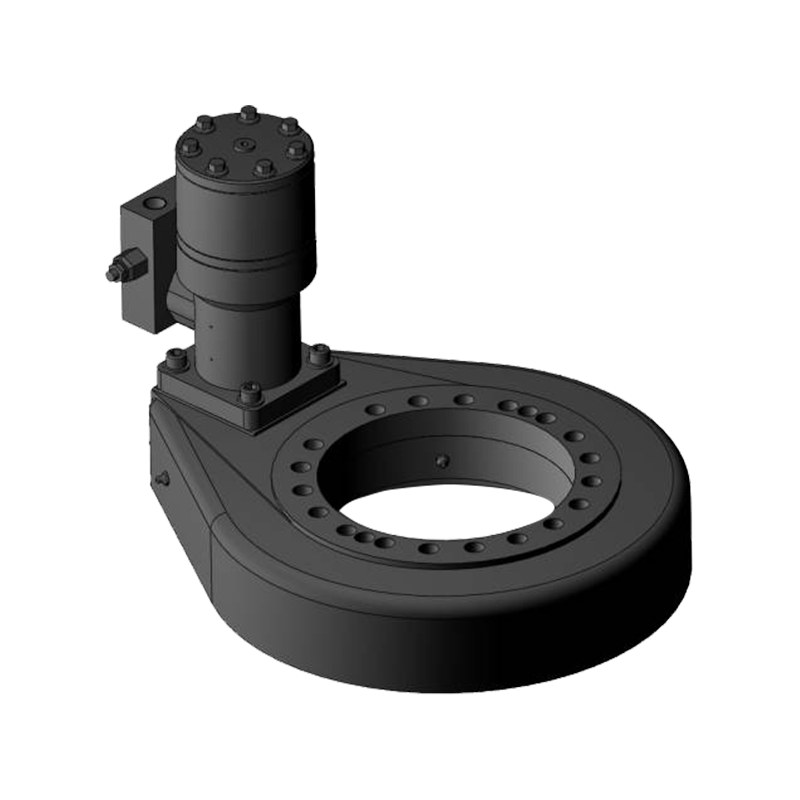

In realm of gravibus-officium mechanica systems, ubi motus gyratorium oportet esse et imperium et robust; Verticalis internum calces slewing agit Emerged ut discrimine solution ad translationem Torque, supporting axial et radiales onerat, et enabling lenis, precise gyrationis. Hos magistra components integralis lateque industriae constructione et renovabili navitas applications, offering pacto tamen potens ad traditional occidit gestus et externum coegi systems.

Dissimilis horizontalis aut extrinsecus apparatus sistit machinationes, vertical internum calces sleywing agit integrate in calces dentes intra gyratorium structure - typically hasta intra signatum, verticaliter orientatur Gearbox. Hoc consilio non solum enhances tutela contra environmental contaminantium sed etiam amplio onus distribution, augetur operational efficientiam, et reduces lapsum in tempore.

Hoc articulum exploratoriam principiis, eget commoda et expanding applications vertical internum calces slewing agit, quatenus crescente momenti in modern ipsum et automation.

Structural consilio et mechanica functionality

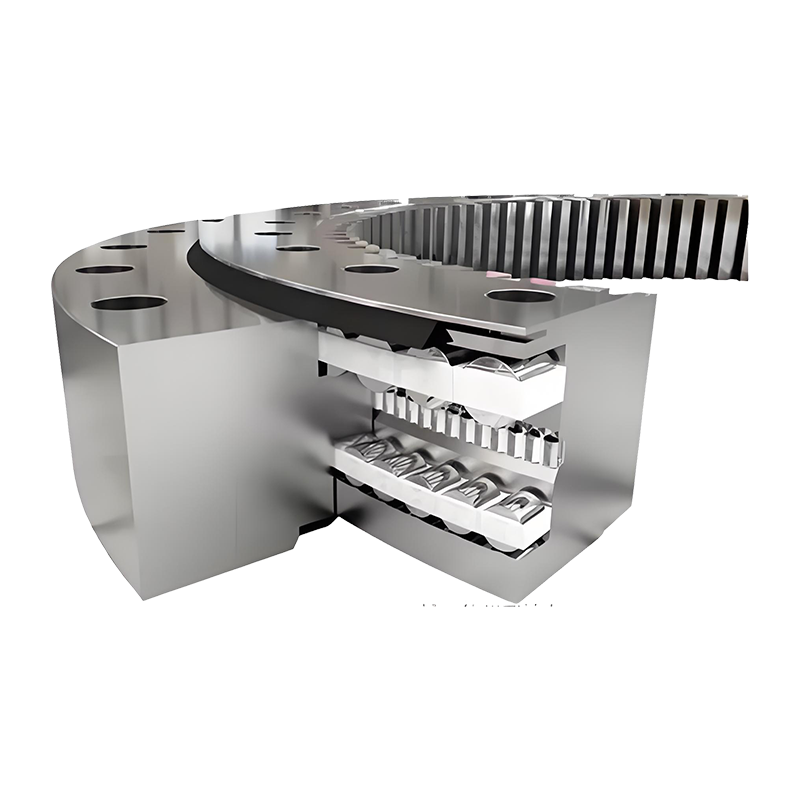

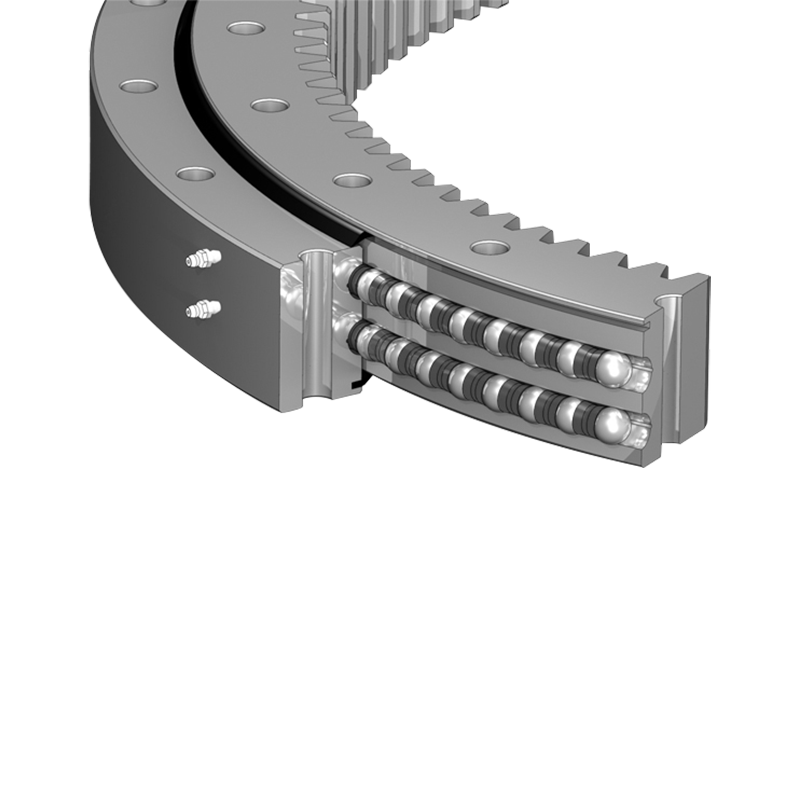

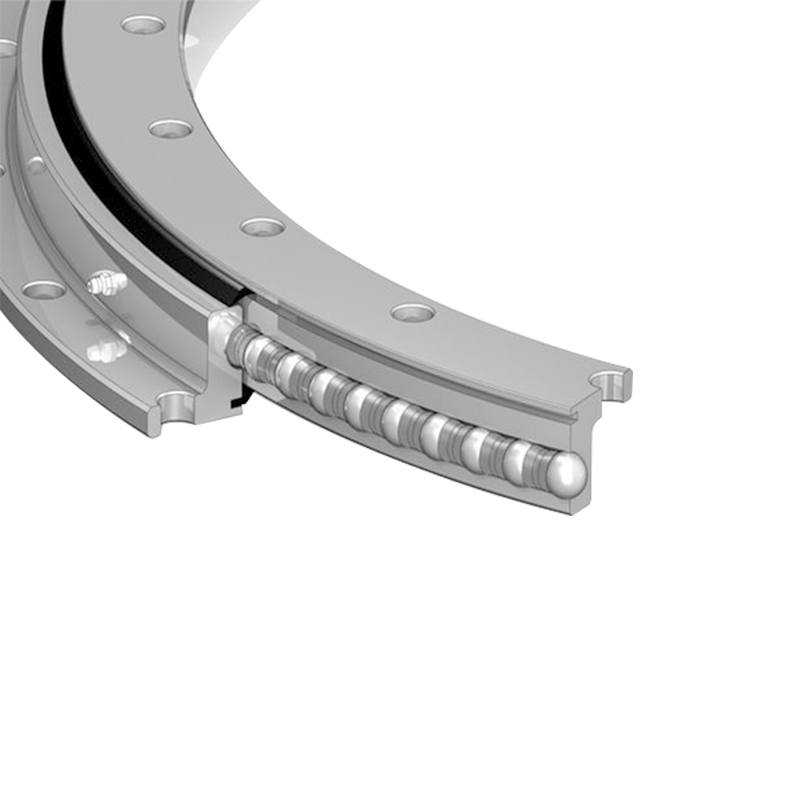

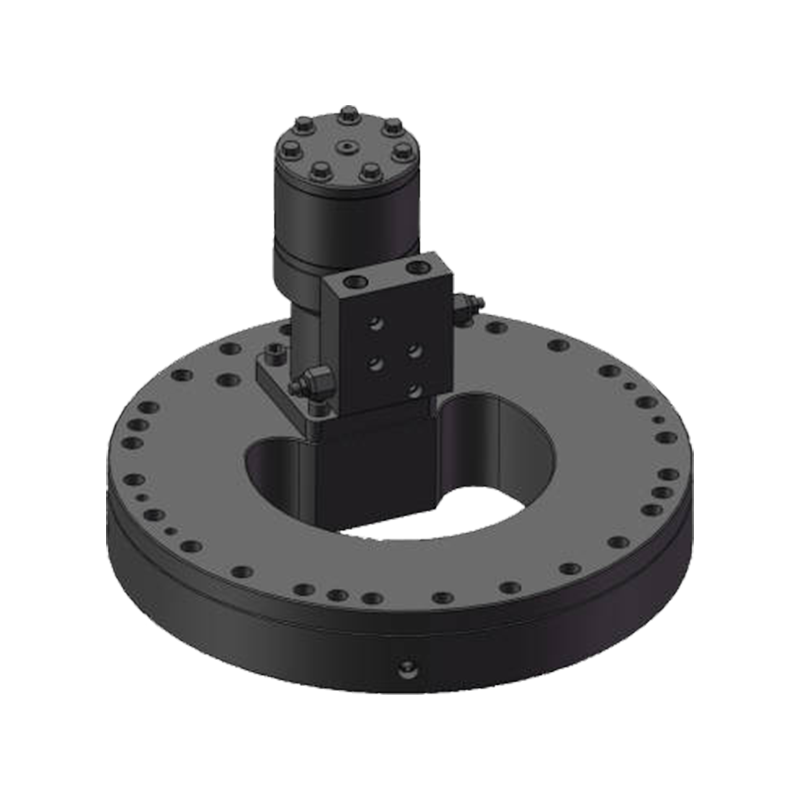

Core ad core, internum calces sistit coegi consistit in centralis Pionum calces quod in pennis cum pennis anterius anulus calces. Hoc configuratione concedit ad gyratorium motus dum maintaining a excelsum gradu mechanica stabilitatem. Systema est saepe integrated cum praecisione gestus, quod support ambo axial (falcem) et radiale (lateralis) onerat, faciens idoneam ad applications involving dynamic viribus et off-centrum pondus distribution dynamic et off-centrum pondus distribution.

Key Structural elementa includit:

Internum anulus calces: posita circa exteriores perimetrum rotating suggestu, hoc calces praebet magnum contactus superficiem ad Pinter, cursus et onus transitum.

Pinus coegi ratio: typically pulsus per electrica vel hydraulicis motricium, in secreto, cum internum calces ad initias et control gyratorium motus.

Conventus, summus capacitas cylindro aut pila gestus sunt incorporatus ut manage multidirectional viribus, permittens systema praestare per postulans conditionibus.

Inclusum habitationi: protegit internum components a pulvis, humorem et obstantia, enhancing Vivacitas et reducing sustentacionem necessitates.

In verticali orientation de coegi adhuc optimizes spatium utendo, praecipue in installations ubi area vestigia aut altitudo cohiberi sunt considerations.

Effectus commoda super traditional sauuit systems

Verticalis internum calces sucus agit offer aliquot distincta commoda comparari conventional occidit machinationes ut aperta calces systems aut extrinsecus percussit gestus:

Enhanced Load capacity: Quod internus calces consilio concedit pro magis uniformis vis distribution trans Tullius calces dentes, augendae resistentia ad concursorum loading et lassitudine.

Improved obsignationem et tutela: inclusum housings ne contaminationem et retinere lubricatae, extendens servitium vitae etiam in dura ambitus.

Superiore Aureus Efficens: cum reducitur backlash et optimized calces proelio, hi agitet libera levior operatio et melior industria translatio.

Foedus integration: sui continebat naturam facit ea specimen pro installations requiring minimal protrusion vel integration in stricta spatia.

Reducitur sustentationem: comparari ad expositae Gears aut aperta gestus, internum calces sucus agitet requirere minus frequentes servicing et lubricatae.

Hae beneficia et vertical internum calces slewing agit maxime bene-idonea ad applications, ubi reliability et diu term perficientur sunt essential.

Applications per Industrial Sectors

In versatility et diuturnitatem vertical internum calces sleywing agit, duci ad adoptionem in diverse ordinata industries, singulis benefiting a unique mechanica proprietatibus:

I. Ventus Energy

In ventus turbines, praesertim YW et picem imperium systems, haec agitent curare precise alignment of rotor laminis cum ventus directionem, optimizing industria captis et obscura mechanica accentus.

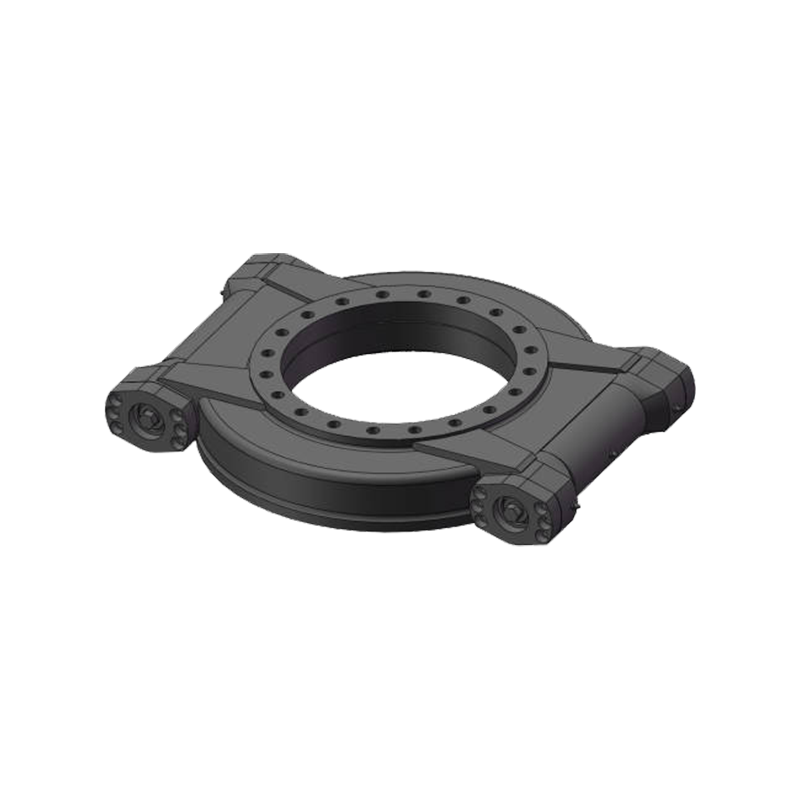

II. Construction et gravibus machinery

Turris in usus, excavators et mobile elevatis tabulatis adlevatae, ut enable firmum, CCCLX-gradu gyrationis sub gravibus onerat dum servata operator salutem et imperium.

III. Marine et Offshore Equipment

Integrated in navem ono oneratorem, Offshore EXERCITATIO Rigs et portum Grues, providere certa gyratorius motus in altus-corrosio, summus vibrationis environments.

IV. Material tractantem et Automation

Applicari in automated repono et retrieval systems (ut / Rs), robotic turntables et TRADUYOR Rotators, ubi consistent, programmable gyrationis non requiritur.

V. Solaris tracking Systems

Support dual-axis tracking aggeris sequi solis semita per diem maximizing photovoltaic efficientiam sine compromingtural integritas.

Quisque applicationem elucidat adaptability verticalis internum calces slewing agit ad varianos onus profiles, environmental conditionibus et praecisione requisitis.

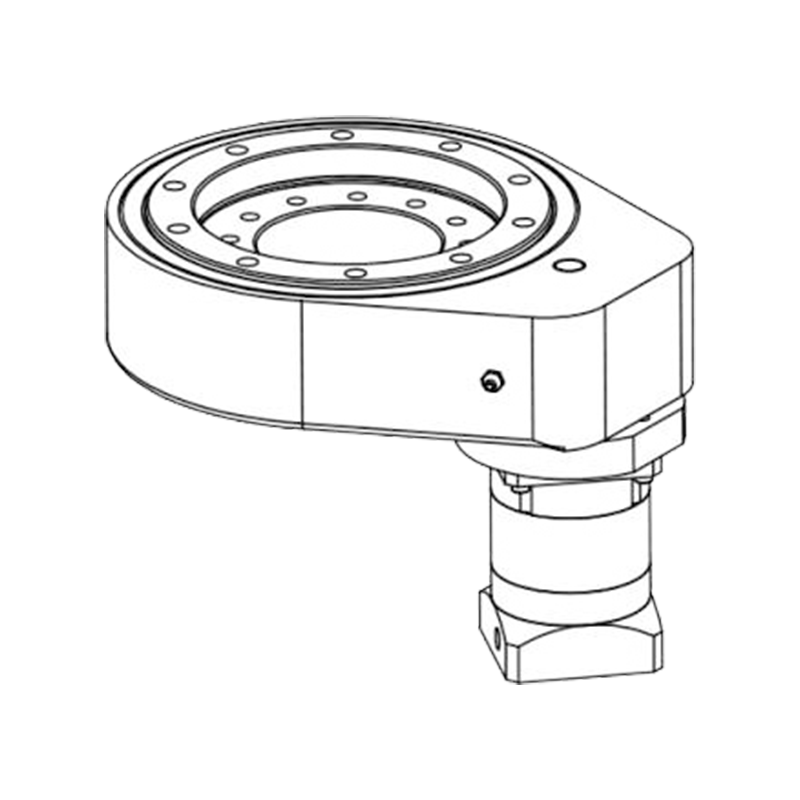

Integration cum modern potestate systems

Ut industriae automation continues evolve, vertical internum calces sistit in agitibus sunt magis paria cum provectus imperium technologiae ad augendae functionality et docilitate:

Servo et stepper motor integrationem: sino quod praecise angularis positioning et programmable motus profile.

Digital Feedback Systems: encoders et soles providere real-vicis positio data, enabling clausa-loop potestate et errorem disciplinam.

Conditionis Cras Sensors: Vibrationis, Temperature et Torque sensoriis potest embedded ad deprehendere mane signa et labore aut misalignment.

Remotis Diagnostic et Predictive Sustentacionem: Connectivity via IOT Platforms enables Vigilantia et Predictive Alerts, reducendo uncomplance downtime.

Haec profectus non solum amplio operational accurate sed etiam contribuere ad smarter, magis dociles machinery capaces capax adaptans mutantur conditionibus in musca.

Provocationes et considerations in implementation

Dum verticalis internum calces sucus agit offerre significant technica commoda quaedam challenges oportet addressed per implementation:

Design Complexity: Propriis integration requirit diligenter analysis de onus dynamics, adscendens figuras, et alignment tolerances.

Initial sumptus, comparari simpliciter sistit solutiones, internum calces agitet potest portare superior upfront costs ex eorum praecisione ipsum et conclusus consilio.

Lubrication Requirements: obstante signatus habitationi, periodica inspectionem et rursus lubricatae sunt necessaria ponere meliorem perficientur.

Thermal Expansion, in velit aut summus temperatus applications, differentiale expansion inter materiae potest afficit calces meshing et afferentem preload.

Caveant planning et cooperationem cum experienced mechanica engineers sunt crucial ad ensuring prospere deployment et longa-term reliability.

Innovations et futura directiones

Vultus praemisit, ongoing investigationis et development nisus sunt focused in meliorem efficientiam, adaptability, et sustineri vertical internum calces sistit:

Eminentive Manufacturing: 3D-typis calces components sunt explorantur ad redigendum pondus et proventus customization sine comprominging vires.

Auto-lubricating materiae: progressionem compositi vel Ceramic-secundum Gears quod minimize opus externum lubricatae et redigendum sustentationem postulat.

Smart Gentes et Integrating Act: Incorporation intelligens afferentem systems quod miscere sentire, actioni, et sistit munera in unum unitas.

Energy Recuperatio machinationes: Explorationis Regeneratia Braking Systems quod captis motu industria durante retardatione pro reuse in hybrid et altilium-Lorem apparatu.

Haec innovations punctum ad futurum, ubi vertical internum calces slewing agitet ludere an maius partes in sustineri, intelligentes, et autonomus mechanica systems.