Quam ad curare stabilitatem et reliability trium-row cylindro sistit in extrema operantes condiciones?

2024.09.05

2024.09.05

News industria

News industria

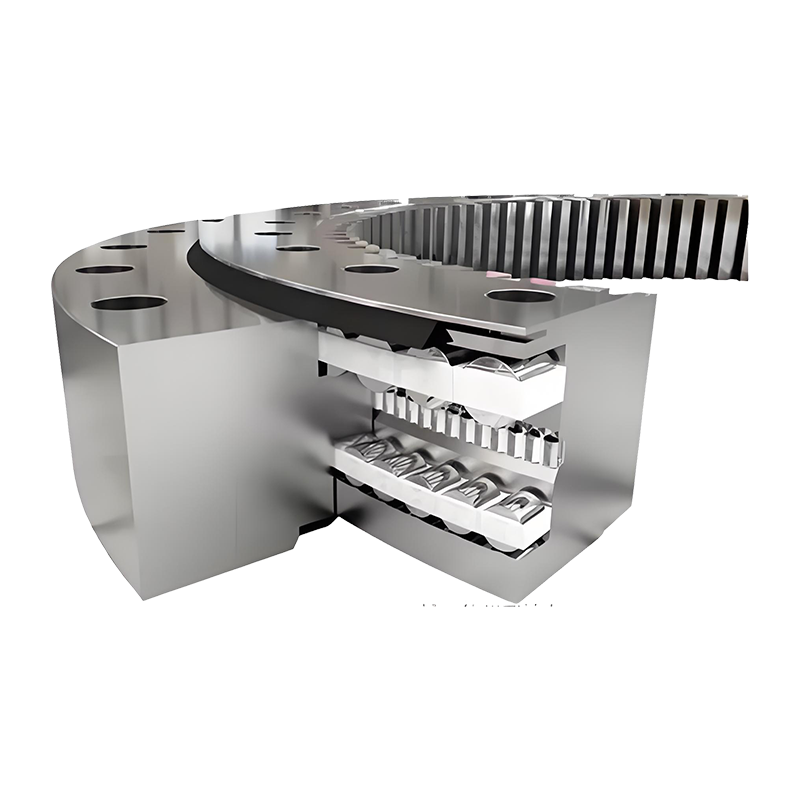

Ensuring stabilitatem et reliability de Tres-row cylinder slewing afferentem Sub extrema operantes condiciones est crucial. Infra sunt quidam clavis mensuras superiores:

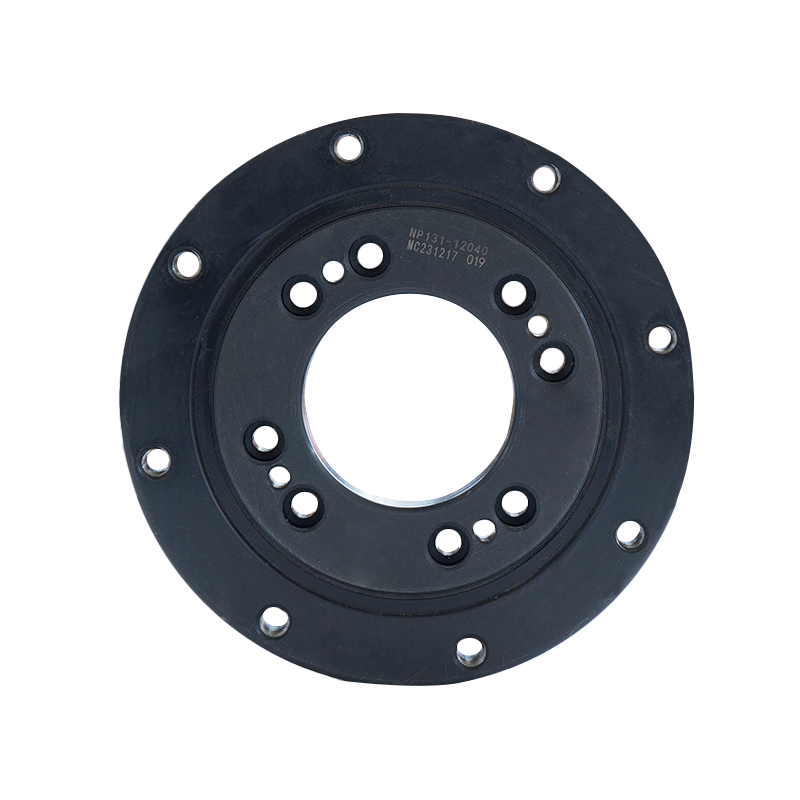

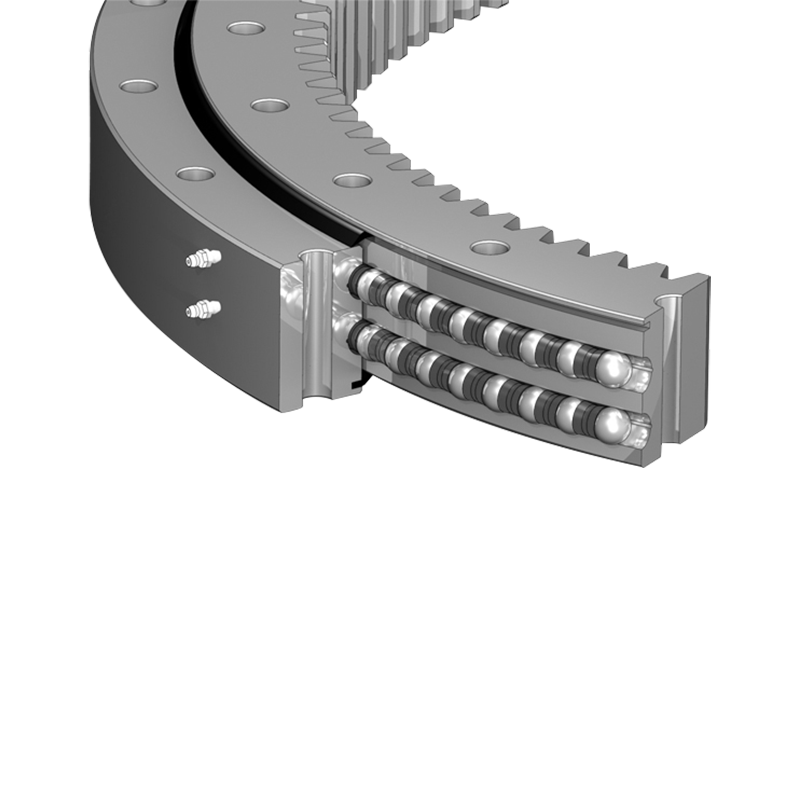

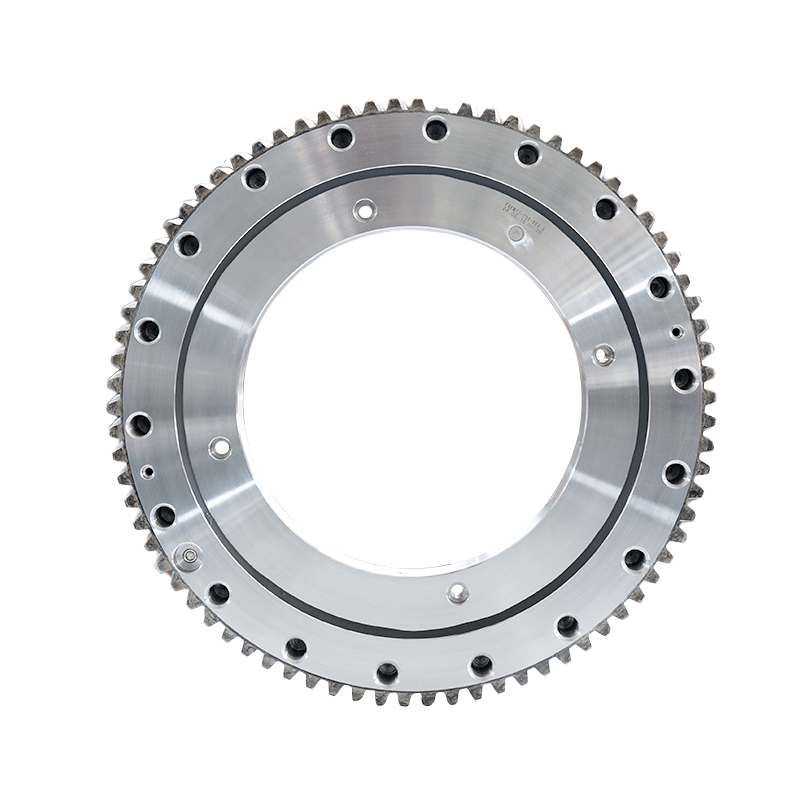

Augendae structural fortitudinem, sub extremam operationem condiciones, altior-viribus materiae debet esse ad officiosum clavis components de lateribus, ut lacus, ut onus et ad redigere et ex lassitudine, ita improving et ad redigere in singulis, ita improving et ad redigere in singulis, ita improving et ad redigendum in singulis, ita improving et ad redigere in singulis, ita improving et ad redigere in singulis, ita improving et ad minuere et ad diamet.acrus Calculation and Selection:Accurately calculate the required type and specification of the slewing bearing based on the actual load, operating conditions (such as speed, temperature, humidity, etc.), and the working environment (such as corrosive gases or liquids).Choose high-quality brand products that have undergone rigorous testing and verification to ensure the bearing's quality and performance meet the requirements of extreme working conditions.

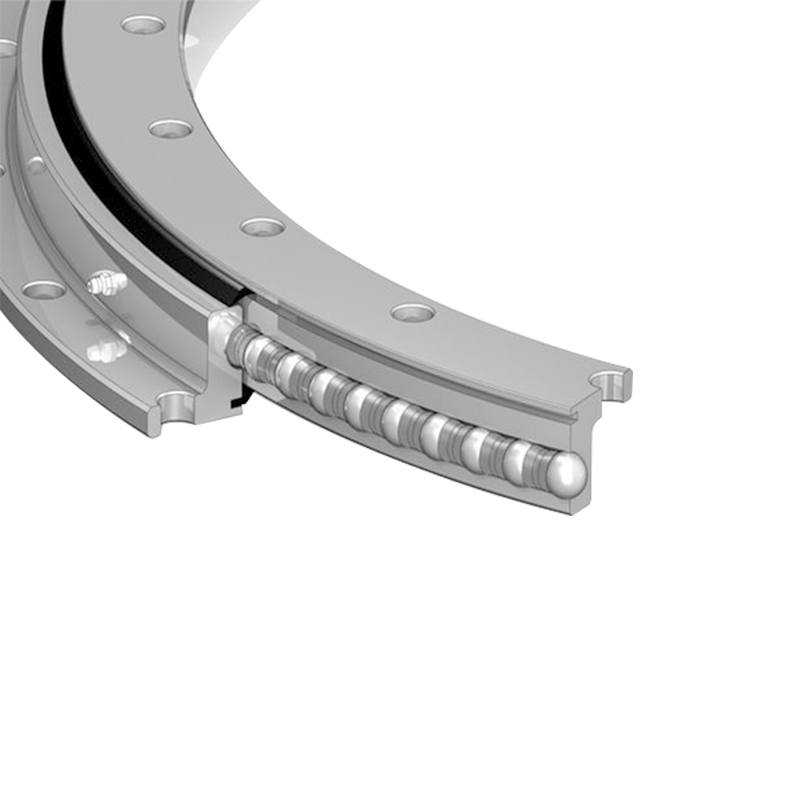

Regular Lubrication:Under extreme working conditions, increase the frequency of grease application and use higher-performance lubricants to ensure good lubrication between the raceways and rollers, reducing friction and wear.Regularly check the working condition of the lubrication system to ensure sufficient and even distribution of grease.Inspection and Replacement:Regularly inspect the wear conditions of the raceways, rollers, and seals of the slewing bearing and promptly repair or replace damaged parts.Pay special attention to the sealing performance of the bearing to prevent external contaminants and moisture from entering and causing corrosion and damage.Cleaning and Protection:Regularly clean debris and dirt from the surface of the slewing bearing to keep it clean and dry.In corrosive environments, take necessary protective measures, such as applying anti-corrosion coatings or installing protective covers.

Accurate installation: Per installation, sequantur installation guidelines provisum est a fabrica ut installation accuracy, ut gradu et coaxiality, occurrit ad inspection.use et temperatio mensuræ et apparatu ad installation.Utment, post installation, uterentur necessarium committendas et iudicii, si non sunt, operantibus et si sunt Abnormes sonitus vel vibrations.Make correspondentes adjustments et optimizations fundatur in commissione praecessi ut stabilitatem et reliability de portantes in extrema operationem conditionibus.

Real-Time Monitoring:During equipment operation, monitor the operating status and parameter changes of the slewing bearing in real time, such as temperature, vibration, and noise.Use advanced monitoring systems and sensors to conduct real-time monitoring and data analysis of the bearing to identify potential problems promptly and take appropriate measures.Early Warning Mechanism:Establish a comprehensive early warning mechanism and set early warning thresholds based on the trends and patterns of In monitored data.If ad monitored notitia excedit ad mane admonitio limine, statim exitus analert et accipere correspondentes subitis mensuras ad vitare afferentem defectum vel accidentia.

Optimis consilio et lectio confirmandam sustentationem et cura, improving installation et committerat praecisione, et enhancing magna et mane monitionem, firmitatem et reliablity in tres ordine cylindro slewing potest esse in extrema conditions.